Anping Kexing Wire Mesh Manufacturing Co., Ltd.

1Yr

Main Products: Metal wire rope, Welded Wire Mesh, Fencing mesh

Home > Company Introduction

Company Overview

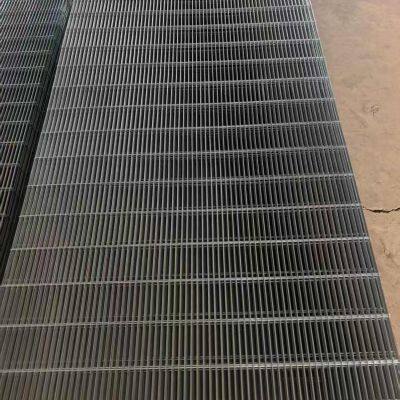

Anping County Kexing Silk Mesh Manufacturing Co., Ltd. is a specialized enterprise rooted in Anping County, Hengshui City, Hebei Province—China’s premier hub for wire mesh production, boasting a mature industrial chain and rich sector expertise. Founded on May 17, 2021, it operates as a natural-person-owned limited liability company, led by legal representative Cheng Hang, who oversees daily operations and strategic development. Registered with Anping County Market Supervision and Administration Bureau, the company holds unified social credit code 91131125MA0GCQ4T0P (also its taxpayer ID), paired with organizational code MA0GCQ4T-0 and business registration number 131125000200170. Its registered capital is 1 million RMB, with a 2021–2051 business term that signals long-term growth plans. Based at No. 20 Sijing Road, Anping (postcode 053600), it taps into the region’s robust supporting resources—including raw material suppliers, component manufacturers, and logistics networks—to streamline production and distribution. Classified under “Manufacture of Metal Wire Ropes and Their Products (C3340)”, Kexing’s core focus includes specialized wire mesh machinery alongside related products. Its business scope covers: manufacturing of wire mesh equipment (e.g., wire mesh weaving machines, welding machines, cutting machines, shaping machines, and customized processing devices), metal processing machinery, electromechanical equipment, and industrial control systems; sales of mechanical parts (plus processing services), building materials, and textile-specific equipment; production and sales of metal wire ropes, wire mesh products, and non-licensed special equipment; industrial control device sales; and cargo import/export (all activities comply with legal requirements, excluding pre-approved items). At the heart of Kexing’s offerings are its wire mesh machinery lines, tailored to diverse industrial needs. Its weaving machines process materials like stainless steel, low-carbon steel, and galvanized wire to produce square, hexagonal, or crimped mesh—used in construction, agriculture, and filtration. The welding machines deliver high-precision joins for guardrail nets, construction mesh panels, and animal husbandry fences, ensuring structural stability. Cutting and shaping machines provide customized sizing, letting clients obtain tailored wire mesh products for unique operational demands. These machinery lines are complemented by durable metal wire ropes and finished wire mesh, crafted via advanced techniques to meet industry quality standards. Operationally, Kexing maintains an “existing (operating)” status, with its latest approval date updated to January 7, 2026—reflecting strict compliance with local regulations. Leveraging Anping’s industry cluster advantages, Kexing optimizes efficiency by sourcing high-quality raw materials locally, collaborating with nearby component suppliers for timely parts access, and using regional logistics to fulfill domestic and international orders. It also enforces strict quality control: from raw material inspections to finished product testing, every stage adheres to rigorous protocols to meet client expectations. Looking ahead, Kexing aims to expand domestic and global market reach via import-export channels, introducing its wire mesh machinery to more regions while integrating advanced international technologies to upgrade production capabilities. It will prioritize innovation in intelligent, efficient wire mesh machinery to meet evolving industry needs, and deepen local industrial chain partnerships—with suppliers, distributors, and clients—to build a collaborative ecosystem. With its stable foundation, long business term, and commitment to quality, Kexing is positioned to become a reliable partner in the wire mesh machinery and product sector.

-

HACCP, TL900, QS9000, SA8000, ISO9001, ISO9004, ISO17799, ISO9000, ISO14000, ISO10441, ISO16949, TS16969, ISO19011:2000, OHSAS18001, OthersProduct Certifications

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic MarketMain Markets

-

Hengshui, Hebei, ChinaLocation

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

HACCP, TL900, QS9000, SA8000, ISO9001, ISO9004, ISO17799, ISO9000, ISO14000, ISO10441, ISO16949, TS16969, ISO19011:2000, OHSAS18001, Others Product Certifications

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Stainless Steel Wire Mesh Main Industry

-

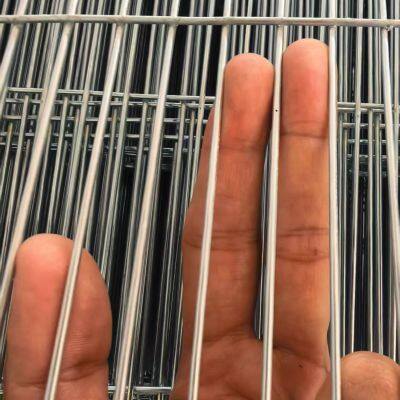

Quality ControlQuality is Kexing’s cornerstone, and we enforce a rigorous, multi-stage system to meet industry-leading standards. We start with raw materials: only high-grade stainless steel, low-carbon steel, and galvanized wire from trusted Anping suppliers are used, with each batch tested for tensile strength and corrosion resistance before production. During manufacturing, every machine undergoes 3 in-process inspections: weaving machines run 24 consecutive hours to verify mesh consistency; welding machines are checked for 0.1mm joint precision. Finished products get final validation (load-bearing tests for frames, stability assessments). We also comply fully with national industry rules (category C3340), with all products paired with quality certificates. Post-delivery, quarterly client follow-ups track performance, and feedback refines our processes—ensuring every Kexing product delivers long-lasting, reliable value.

Quality ControlQuality is Kexing’s cornerstone, and we enforce a rigorous, multi-stage system to meet industry-leading standards. We start with raw materials: only high-grade stainless steel, low-carbon steel, and galvanized wire from trusted Anping suppliers are used, with each batch tested for tensile strength and corrosion resistance before production. During manufacturing, every machine undergoes 3 in-process inspections: weaving machines run 24 consecutive hours to verify mesh consistency; welding machines are checked for 0.1mm joint precision. Finished products get final validation (load-bearing tests for frames, stability assessments). We also comply fully with national industry rules (category C3340), with all products paired with quality certificates. Post-delivery, quarterly client follow-ups track performance, and feedback refines our processes—ensuring every Kexing product delivers long-lasting, reliable value. -

Our ServicesAnping County Kexing Silk Mesh Manufacturing Co., Ltd. delivers tailored, one-stop solutions centered on its core wire mesh machinery and supporting products—designed to fit industries like construction, agriculture, filtration, and animal husbandry. For construction clients, we provide high-tensile wire mesh weaving machines (for concrete reinforcement mesh) paired with on-site installation guidance, ensuring seamless integration into existing production lines. Agricultural partners get custom hexagonal wire mesh welding machines (ideal for farm fences) plus precision cutting services to match unique field sizes. Beyond equipment supply, we offer end-to-end support: pre-sales consultations to match machinery to production scales, in-depth operator training to boost efficiency, and 24-hour after-sales maintenance for urgent issues. For international clients, we handle streamlined import/export procedures (documentation, logistics) to ensure timely, hassle-free delivery. Whether you need a single weaving machine or a full production line, our services balance flexibility, efficiency, and long-term value for every partner.

Our ServicesAnping County Kexing Silk Mesh Manufacturing Co., Ltd. delivers tailored, one-stop solutions centered on its core wire mesh machinery and supporting products—designed to fit industries like construction, agriculture, filtration, and animal husbandry. For construction clients, we provide high-tensile wire mesh weaving machines (for concrete reinforcement mesh) paired with on-site installation guidance, ensuring seamless integration into existing production lines. Agricultural partners get custom hexagonal wire mesh welding machines (ideal for farm fences) plus precision cutting services to match unique field sizes. Beyond equipment supply, we offer end-to-end support: pre-sales consultations to match machinery to production scales, in-depth operator training to boost efficiency, and 24-hour after-sales maintenance for urgent issues. For international clients, we handle streamlined import/export procedures (documentation, logistics) to ensure timely, hassle-free delivery. Whether you need a single weaving machine or a full production line, our services balance flexibility, efficiency, and long-term value for every partner. -

Company HistoryRooted in Anping County—the “Wire Mesh Capital of China”—Anping County Kexing Silk Mesh Manufacturing Co., Ltd. launched in May 2021, born from a sharp insight into the local industry’s demand for specialized, cost-effective wire mesh machinery. In its early days, the company focused on refining core weaving machine designs, leveraging Anping’s decades-long wire mesh craftsmanship heritage to boost equipment precision and durability. By 2022, fueled by positive market feedback, Kexing expanded its line to include welding and cutting machines, catering to broader industrial needs. Throughout its growth, it has upheld strict regulatory compliance: from securing its business registration (code 91131125MA0GCQ4T0P) to updating operational approvals in January 2026. In just 5 years, Kexing evolved from a niche machinery producer to a comprehensive solution provider, deepening ties to Anping’s industrial chain and earning recognition for reliable, budget-friendly products.

Company HistoryRooted in Anping County—the “Wire Mesh Capital of China”—Anping County Kexing Silk Mesh Manufacturing Co., Ltd. launched in May 2021, born from a sharp insight into the local industry’s demand for specialized, cost-effective wire mesh machinery. In its early days, the company focused on refining core weaving machine designs, leveraging Anping’s decades-long wire mesh craftsmanship heritage to boost equipment precision and durability. By 2022, fueled by positive market feedback, Kexing expanded its line to include welding and cutting machines, catering to broader industrial needs. Throughout its growth, it has upheld strict regulatory compliance: from securing its business registration (code 91131125MA0GCQ4T0P) to updating operational approvals in January 2026. In just 5 years, Kexing evolved from a niche machinery producer to a comprehensive solution provider, deepening ties to Anping’s industrial chain and earning recognition for reliable, budget-friendly products. -

Our TeamAt Kexing, our strength lies in a compact, high-impact team united by wire mesh industry expertise and a client-first mindset. Leading the team is Cheng Hang, our legal representative—an Anping local with 10+ years in wire mesh equipment manufacturing, whose on-the-ground knowledge of industry pain points guides product development. Our 5-person technical team includes seasoned engineers with decades of Anping-based experience; they blend traditional craftsmanship with modern techniques (e.g., boosting weaving machine speed while preserving mesh uniformity). Our client service team prioritizes on-site engagement: they visit production sites to spot workflow bottlenecks, then collaborate with engineers to tailor solutions. Though we use flexible, agile staffing (aligned with early-stage growth), every member brings specialized skills—ensuring personalized, expert support for every client, no matter the project scale.

Our TeamAt Kexing, our strength lies in a compact, high-impact team united by wire mesh industry expertise and a client-first mindset. Leading the team is Cheng Hang, our legal representative—an Anping local with 10+ years in wire mesh equipment manufacturing, whose on-the-ground knowledge of industry pain points guides product development. Our 5-person technical team includes seasoned engineers with decades of Anping-based experience; they blend traditional craftsmanship with modern techniques (e.g., boosting weaving machine speed while preserving mesh uniformity). Our client service team prioritizes on-site engagement: they visit production sites to spot workflow bottlenecks, then collaborate with engineers to tailor solutions. Though we use flexible, agile staffing (aligned with early-stage growth), every member brings specialized skills—ensuring personalized, expert support for every client, no matter the project scale.